We might consider a Liebherr in the Mid-Atlantic region because it fits the building heights and alley ways in urban areas. “We have chosen certain cranes lately based on different manufacturers having different capacities with outrigger positioning, boom length and counterweight positioning. “Beyond the environment the crane is going to be working in, you have to look at the types of jobs you will be performing,” Wilson said. Beyond capacity and reach, one must consider transportability, ease of operation and price. There are also many considerations when purchasing an all-terrain crane, Wilson said. ATs are really ideal when the site conditions require you to be more nimble, to make difficult roadway and site turns.” “There are many more benefits of an AT than you can’t get with a truck crane, like the hydraulic suspension.

.jpg)

“With the AT you have the ability to steer front, rear and crab/drive sideways to get into position and get the necessary the tail swing you need,” he said. For this reason, all terrain cranes can be the ideal lifting solution, Wilson said. M-L Holdings operates all terrain cranes in urban areas where narrow streets and congested roadways are an issue, and the company also uses cranes in mountainous areas where climate changes and soil conditions complicate crane setup. Furthermore, the 21 m double folding main boom extension from the five-axle family is compatible with the new Demag AC300/6, hence improving cost savings for owners with existing Demag Cranes.Like all Grove GMK cranes with CCS, the GMK3060L features the MAXbase option for variable outrigger settings and increased load charts in certain working ranges.

The new 300-tonne mobile crane shares the same parts with Demag five axles family.

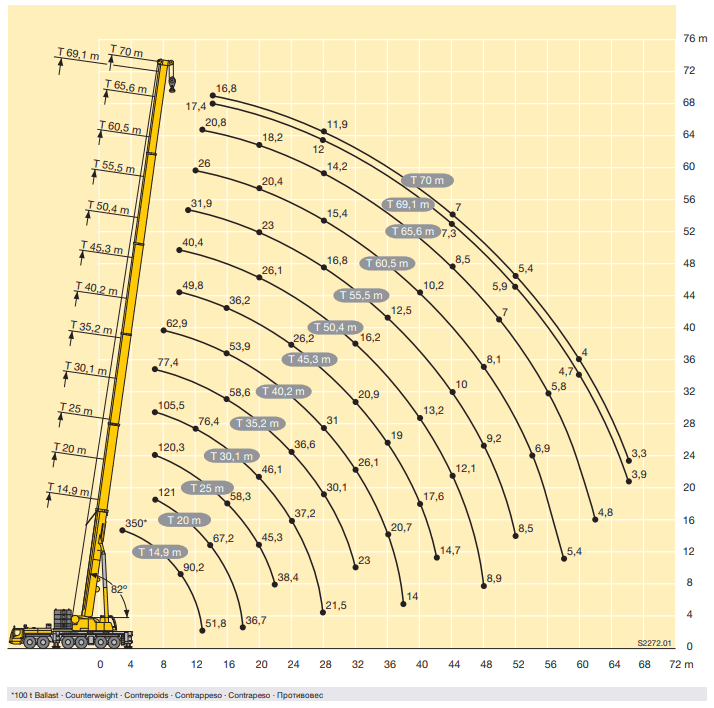

It has also been equipped with Demag’s latest IC-1 Plus control system to allow asymmetric outrigger positioning.Īpart from that, one of the greatest advantages will be the reduction in spare parts inventory for some of the existing Demag crane owners. This includes the start-stop system to minimize idling time, improving fuel consumption and reduce the number of engine hours for better resale value. It was designed to have the same luffing jib rigging system as the larger AC350/6 and AC1000/9.Īnother similarity to the AC1000/9, it uses the single-engine concept. In addition, Demag AC300/6 is the smallest in is Demag range to have a luffing jib configuration, with a maximum system length to 118m. One of the targeted applications will be for tower crane erection, which with its fully extended boom, it can still lift a load of 15 tonnes. The 300-tonne mobile crane’s main boom can work at a height of up to 78m or 74m radius.

0 kommentar(er)

0 kommentar(er)